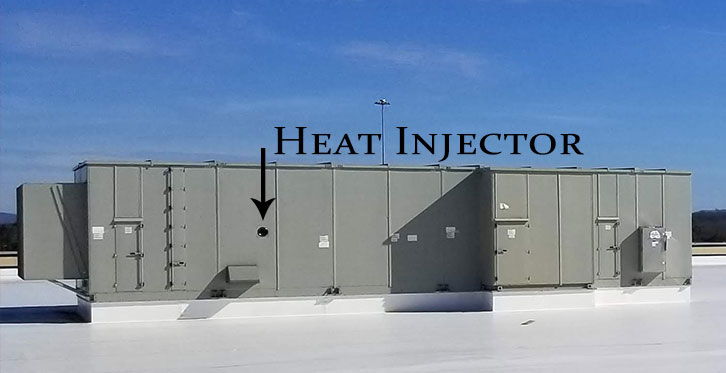

Heat Injector System™

Unique Features

01Savings in Energy

The patented concept of the dedicated combustion blower allows the main airflow to be varied without changing the air-to-fuel ratio on the burner. This unique feature allows the airflow to change to meet the need without having an effect upon the clean combustion. Any reduction in the volume of air that needs to be heated is pure energy savings. The low static load also allows the Air Handler to consume about 30% less energy to move the same volume of air during every hour of operation.

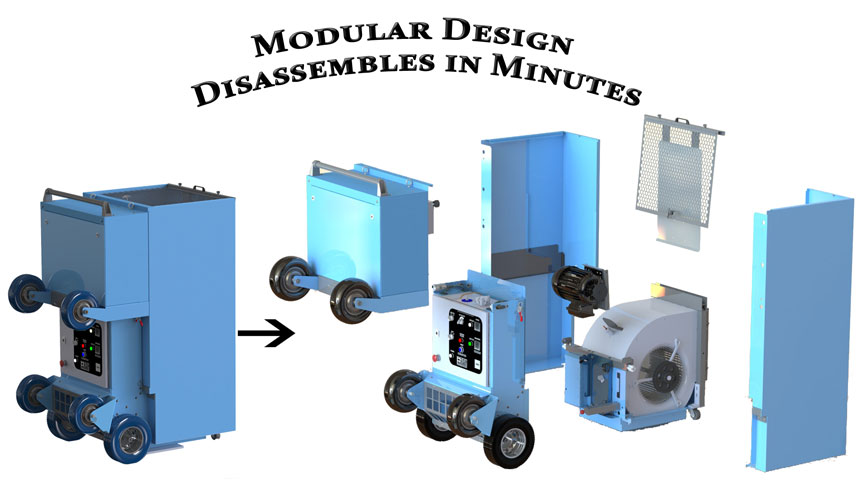

02Flexible Design

The unique features of the Heat Injector™ allow it to be applied to many different processes where heat and airflow are involved. The modular design features, along with the low static load allow the Heat Injector to be successfully applied to address many heat-related issues. The clean heated air from the Heat Injector puts significantly less CO into the environment than the cleanest burning indirect fired heater and will consume less fossil fuel to produce the same heat.

03No Static Load

The patented concept of the dedicated combustion blower creates continuously clean combustion without putting a static load on the airflow. This unique feature allows heat to be injected into any airflow allowing the Heat Injector to solve heating problems in many different industries for both new and to upgrade existing systems. The Heat Injector can be sized to inject sufficient heat to achieve the desired discharge temperature.

About the Heat Injector™

Supplier Support International, Inc. (SSI, Inc) is the parent company of the Heat Injector. David Krupp started SSI, Inc. in July 2001 with the goal to identify problems and design products and processes to solve those problems. The patented Heat Injector (US Patent 7,360,534 and 9,459,022) is the result of this goal. It was introduced to the Industrial and Commercial HVAC Markets in 2010 as a new concept to heat fresh air and recirculated air for buildings and processes.

The patented Heat Injector System consumes less electricity to move the air and reduces the fossil fuel consumption by allowing the airflow to be varied without affecting the clean burning characteristics of the direct gas-fired burner. Those who incorporate the Heat Injector System have a competitive advantage over the competition.

How can we help?

Products

Bed Bug Heating Equipment

The patented Heat Injector System™ uses a unique process to heat and distribute the air to produce the most energy-efficient heat treatment for bed bugs. This patented process uses a dedicated combustion blower that supplies fresh air for the combustion process to allow the heated airflow to be recirculated safely within the space.

The Heat Injector™ uses an industrial blower, powered from any home outlet, to move the maximum amount of airflow using the Automatic HP Boost™. This airflow control automatically adjusts the motor’s speed when additional lengths of the flexible duct are added to achieve the maximum airflow. The volume of air determines the amount of heat that can be transferred into the structure and its contents.

An onboard microprocessor continuously monitors the discharge temperature and automatically modulates the gas (like cruise control) to achieve and maintain the desired discharge temperature.

Direct Fired Duct Heater

The Heat Injector uses a direct gas-fired burner with a dedicated combustion blower which allows the airflow to be adjustable and to reduce the load on the main airflow blower. This allows the air handler to consume about 30% less energy during every hour of operation because the static load of the typical heater is not reduced when there’s not a requirement for heat. Another savings comes from the ability to only heat the amount of air you need. Any reduction in the volume of air that needs to be heated is a direct saving.

The high efficiency of direct gas-fired heat, as compared to indirect heat which has a low high static, low turn-down ratio and the high emissions on the heated exhaust makes the application of direct gas-fired heat an Energy Savings Choice

This heat is so clean – it can be used for recirculated system, and it’s so small – it can be applied in a variety of systems.

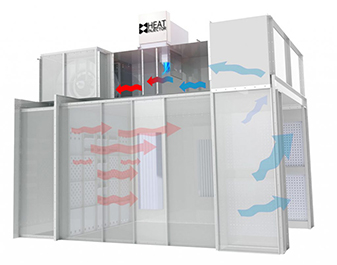

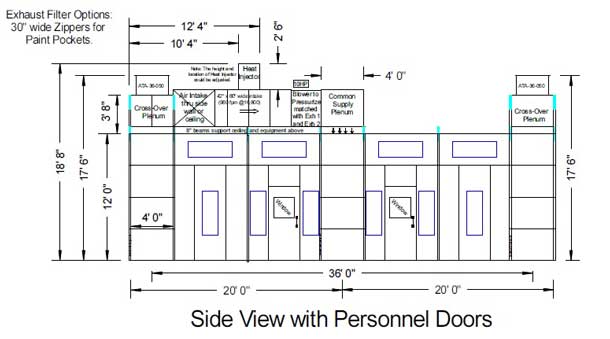

Heated Make Up Air System

When air is exhausted from a facility, an equal volume has to be replaced to maintain a good atmospherical pressure within the facility/enclosure where the air is being exhausted from. The Heat Injector System includes the Air Handler that would be best for your application with a Heat Injector positioned to inject the required heat to achieve the desired discharge temperature. The Heat Injector is also a “module” supplied to Systems Houses who have a responsibility to add heat to the equipment they manufacture. The unique features of no static load with the ability to vary the airflow makes the Heat Injector a wise choice for many applications.

Southern Breeze

When a building is under negative pressure due to active exhausts, and all the doors and windows are closed because it is cold outside, that’s when the Southern Breeze™ is a great approach to the problem. With the low static load on the airflow, the Heat Injector can inject heat into an airflow that is created by opening an access door or damper into the space and routing the airflow through an Injection Chamber where sufficient heat can be injected to cause the air that enters the building to feel like a Southern Breeze. Each situation is a bit different with regard to layout, and special controls will be required for safety, but this is a low energy solution to solve your heating problem.

Note: The negative building prevents the active exhausts from operating well and the indirect fired heaters in the space are about 20% less efficient.