Supply support international has many capabilities, one of our strongest capabilities is to understand how to create an airflow system that is energy-efficient and high performance. Over the last 20 years, SSI developed a relationship with many highly capable manufacturers that are ready to perform when there is a “need”. During the last 10 years, SSI has been finding those “needs”.

One of the greatest needs that SSI has uncovered is the need for an earth-friendly heated air make-up system.

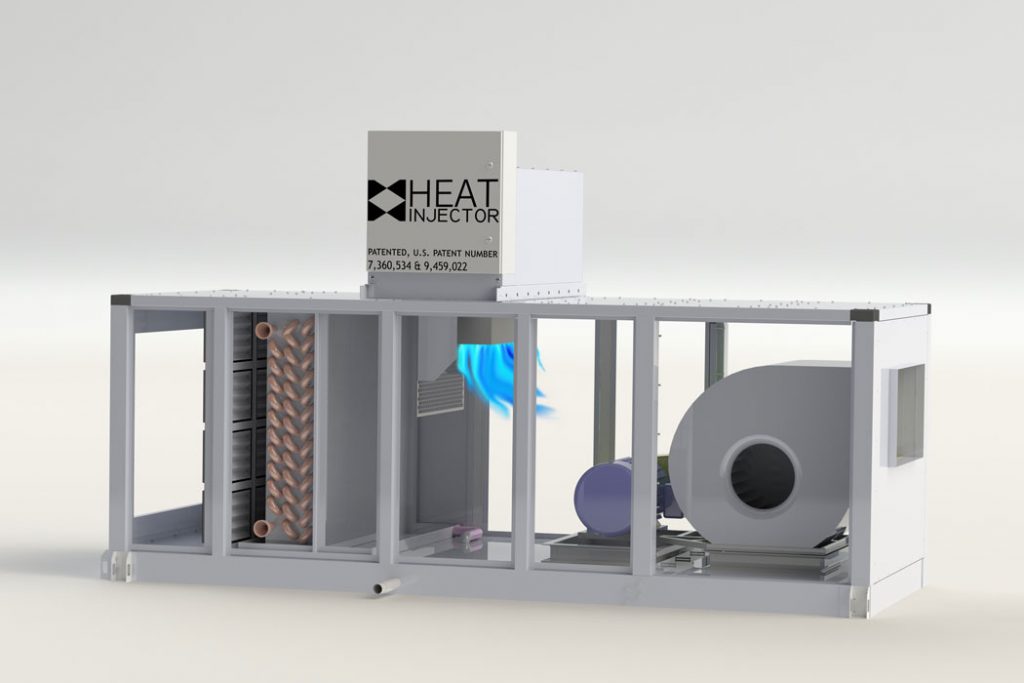

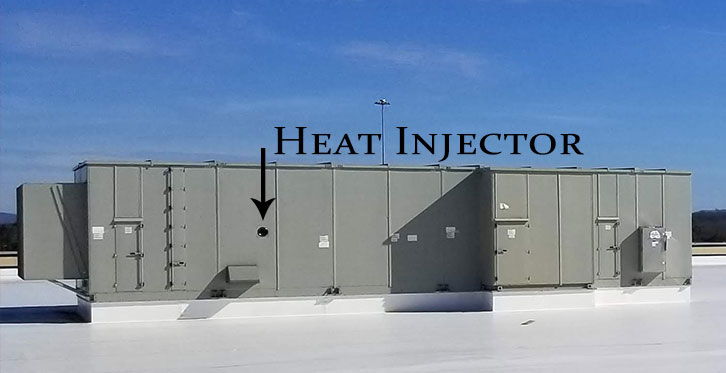

The Heat Injector Team has created a detailed equipment selection tool that will help create the perfect air make-up system for your specific application. We have the capability to create any size air make up system with a large range in airflow volume and heating capacity. Since the patented Heat Injector with a dedicated combustion blower is the most efficient direct fired heater, we are bringing HUGE electrical savings by removing the unnecessary profile plates and removing the static load from the main airflow device.

The advantages of using the concept of the Heat Injector System: